Sand Core and Mold Drying Ovens are used in foundries for drying the coating applied to the sand cores and molds to manufacture high-quality products. The dimensions and heating capacity of the ovens are custom designed and manufactured in accordance with the costumers’ requests and requirements.

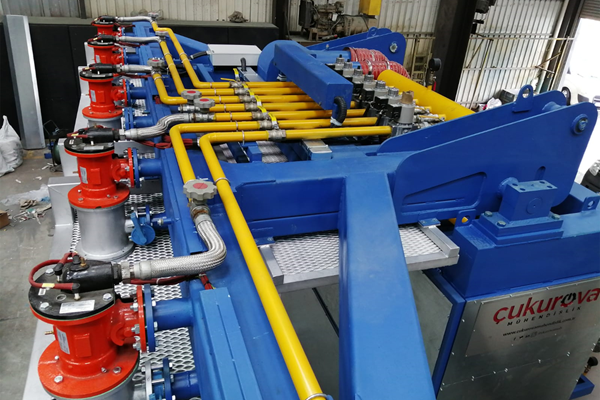

Our Drying Ovens have two types of heating system depending on coating:

Indirect Heating :

Used for solvent-based as well as water-based coatings.

Direct Heating :

Used for water-based coatings. Due to the flue gas temperature being lower, direct heating ovens have more efficient than the indirect heating ovens.

We manufacture two types of ovens depending on indications for use and structural properties:

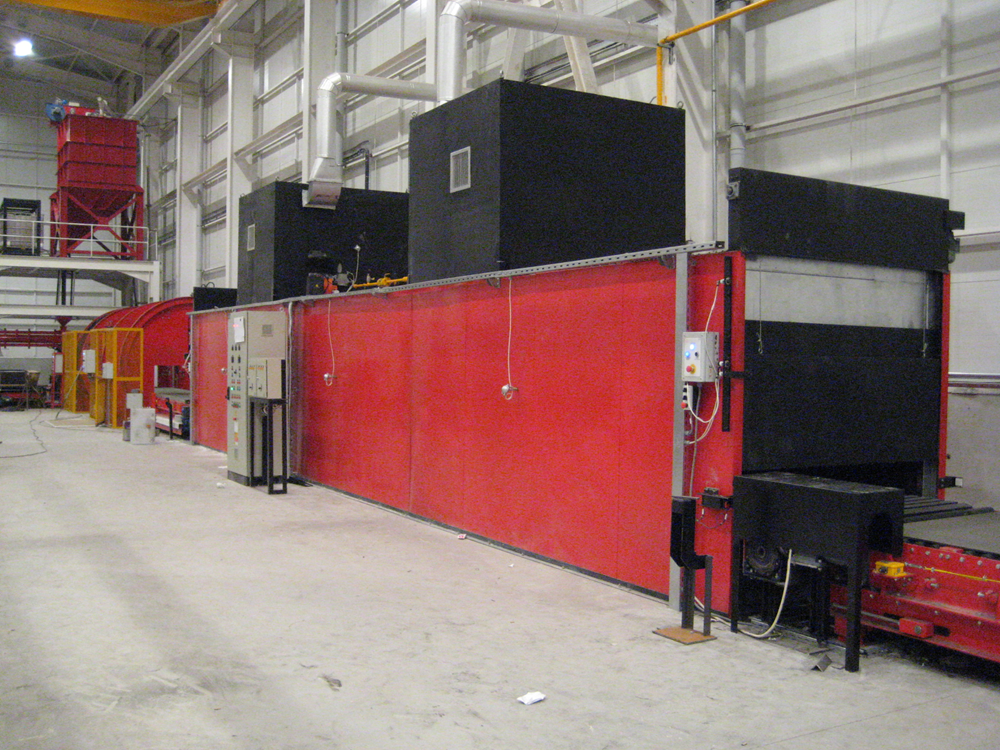

Tunnel Drying Oven :

Sand cores and molds are dried in oven conveyors.

Our tunnel drying ovens consists of 3 zones as preheating, heating and exit.

In order to keep the oven temperature more stable and save energy, lifting gates or air curtains are used at the entrance and exit of the oven.

We manufacture two types of tunnel drying ovens depending on conveyor types:

» Chain conveyor oven

» Wire belt conveyor oven

Batch Oven :

Our batch drying ovens, consisting of 1 zone, are used to dry sand cores and molds in an oven pan trolley.

Türkçe

Türkçe

English

English